Shandong Dingcheng Liye Materials Co., Ltd

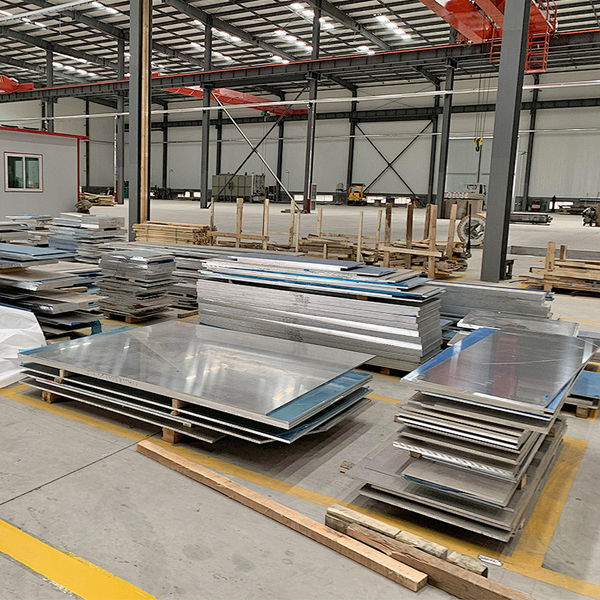

Shandong Dingcheng Liye Material Company is a domestic modern iron and steel enterprise who is founded in 2002. We are committed to carbon steel coil, carbon steel sheet, galvanized coil, galvanized coil, pre-coated coil, pre-coated steel sheet, galvanized tile, pre-coated tile, iron wire, galvanized wire, wire rod, steel bar, stainless steel plate, stainless steel pipe, carbon steel pipe, profile and other steel products.

We are located in Shandong Province and we are close to Qingdao Seaport, that is much convenient in carriage Since our establishment we have always adhered to the business policy of "sincerity, mutual benefit, high efficiency,high quality”tent, to provide stable resources for domestic and foreign large-scale engineering projects for a long time.

Complete specifications, adequate supply, standing inventory of more than 15000 tons.

Company adhering to:"Customer first. A win-win situation"business philosophy. adhere to the "Customer first" principle to provide quality services for our customers. Look forward to working with you and serving you.